FISHBAM AUTOCLAVES

Fishbam manufactures its autoclaves and directly performs its starting up, in addition to offering the instrumental calibration that accompanies the equipment.

Fishbam manufactures its autoclaves and directly performs its starting up, in addition to offering the instrumental calibration that accompanies the equipment.

Designed for the sterilization of food packed in any format: aluminum cans, tin cans, glass jars, pouches, trays, etc.

Valid for pasteurizing and sterilizing different food such as canned fish and seafood, vegetables, fruits, jams, olives, etc.

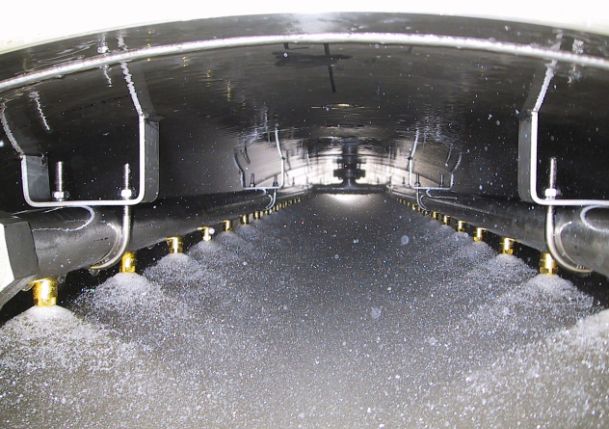

Flexible and adaptable, they are manufactured in stainless steel AISI-304l / AISI-316, in diameters of 1,350 mm and 1,500 mm, fulfilling the requirements of the safety norms and counting with the CE mark according to directive CE 2014/68 / UE of apparatuses under pressure.

Robust and very reliable. Its cooling system reduces sterilization times thanks to a better use of water and sufficient progressivity to avoid thermal shocks or a sudden drop in pressure.

Sterilization and cooling with overpressure by:

Sterilization by: